TEA BAGS

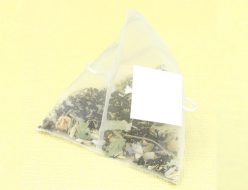

Triangular Tea Bag Processing

The triangular bag is the most popular type of teabag.

Since there are many types of materials, we will make proposals according to the raw materials.

The triangular teabag was the first product we developed in the 1980s.

The bag has a large capacity than a flat teabag, so the tea leaves will spread larger and the aroma and taste are better.

Even though each ingredient has a different experience, the triangular bag is the best option to bring out the solid taste and aroma.

We offer a choice of bag material such as nylon gauze or non-woven fabric, as well as environmentally friendly organic compound esters, to meet the needs of our customers.

The tag that attaches long with the bag could be changed from a short thread to a long thread, depending on the size of the cup. Or you could also use the original design.

Related Products

-

Drip Bag Manufacturing (With “Open Here” Display)

Drip bag tea processing for various tea types such as green tea, black tea, herbal tea, or Chinese tea. By displaying the guidance word "OPEN HERE" in English on the tearing line, it's easy to understand for foreigners to open.

-

Kawaiipack Seasonal Product For [New Year]

The [kawaiipack] product line is manufactured according to the OEM processing method with a special technique. Various sizes and shapes can make into a funny or gorgeous teabag such as cute and goofy characters, cute animals, floral shapes, fashion, messages, and some shapes according to a particular season.

-

Shintomi No. 2 Factory Tea Bag Processing

At the Shintomi no. 2 factory, we are equipped with more sanitary and environmental equipment and are processing tea bags. All of the systems and equipment are meet the requirement of HACCP and suitable for tea bag processing.

-

Add more value to products and goods!!

This is a proposal for businesses and retailers wanting of providing further services beyond the sale of products and goods. *If it is related to tea or sweets, we can prepare it for you.

-

Individually Wrapped Tea Bag Legal Display Printing

Legal display printing on the exterior film. Since it's printed during the manufacturing process, you can reduce the cost of the sticker printing and avoid the trouble of sticking the sticker.

-

Individually Wrapped Triangular Teabag Processing

In recent years, the demand for individually wrapped triangular tea bags has been rapidly increased. To ensure long-term preservation, each package is individually wrapped and filled with nitrogen.

![[Improving the efficiency of pharmacy operations] Making manufacturing records online (with easy steps) [Improving the efficiency of pharmacy operations] Making manufacturing records online (with easy steps)](/wp-content/uploads/2018/03/kusuri_580px_380px-200x200.jpg)

![Seasonal Product [New Year]: Individually Wrapped Teabags Seasonal Product [New Year]: Individually Wrapped Teabags](/wp-content/uploads/2022/01/shougatsu_tb-200x200.jpg)