New Year Product, POWDER STICK PACKS, Seasonal Products, TEA BAGS

Stick Pack Processing With New Design For “New Year”

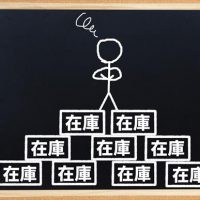

For the celebration of the New Year 2022, we processing stick pack teabag with a special Japanese Traditional Design for the exterior package.

We also accept the creation of a new original exterior package film, or the customer could choose their exterior package film to proceed with the filling process.

If there are any questions regarding this product in particular or any product in general, please feels free to contact us via:

Inquiries TEL: 054-281-9092 (weekdays 9:00 to 17:00)

Email: contact@shizupack.jp

Alternatively, you could contact us using the inquiry form.

Related Products

-

Plain Stick Processing: 35mm Width

The 35mm width plain color stick satchels for various raw ingredients filling process. The stick package’s film has excellent barrier characteristics such as light-shielding, moisture-proof, fragrance-retaining, and some other barrier properties, which are best for food packaging.

-

Organic Powder Green Tea

Stick pack with 25mm width that is suitable for organic powder green tea raw material. The stick pack's film has excellent barrier characteristics such as light-shielding, moisture-proof, fragrance-retaining, and some other barrier properties, which are best for food packaging. In addition, it is easy to cut and can be opened from anywhere on the pack without using scissors.

-

[Seasonal Product For Christmas] “kawaiipack” Product Line

"kawaiipack" is a special product line that has various special designs that aim to make drinking tea looks more fun. And this product will also manufacture with the OEM method. There are many shapes can choose from, such as funny characters, cute animals, favorite wearing clothing, or simple text lines, etc. For Christmas, Santa Clause or Rudolph the reindeer are the most suitable choice.

-

Individually Wrapped Triangular Teabag Processing

In recent years, the demand for individually wrapped triangular tea bags has been rapidly increased. To ensure long-term preservation, each package is individually wrapped and filled with nitrogen.

-

Ester Gauze Teabag Processing

A teabag made of environmentally friendly materials that decomposed into water and carbon dioxide when burned.

-

Triangular Tea Bag Processing

The triangular bag is the most popular type of teabag. Since there are many types of materials, we will make proposals according to the raw materials.

![[50,000 yen per month!!] “Homepage production/Homepage maintenance & management”, “SNS updates” [50,000 yen per month!!] “Homepage production/Homepage maintenance & management”, “SNS updates”](/wp-content/uploads/2019/04/580px_WEB_SITE-200x200.png)

![Seasonal Product [New Year]: Individually Wrapped Teabags Seasonal Product [New Year]: Individually Wrapped Teabags](/wp-content/uploads/2022/01/shougatsu_tb-200x200.jpg)

![[Renewal] Whole Catechin Powder Stick Pack Green Color [Renewal] Whole Catechin Powder Stick Pack Green Color](/wp-content/uploads/2022/04/new_marugoto_green-1-200x200.jpg)