POWDER STICK PACKS

[Reduce CO2 Emission] Introducing “Biomass-derived Ink” For Stick Pack Film Printing

The “biomass-derived ink” has been used for our stick pack film printing process.

Inks made from plant-derived resources (using rice bran, seeds, etc.) are expected to generate about 13% less CO2 than conventional oil-based gravure inks.

Following the term “decarbonization”, the word that attracts the attention of the environmentalist in particular and the people who care about protecting the environment in general, for solving environment-related social issues such as the declaration of zero greenhouse gas emissions by 2050.

We will continue to propose using environment-friendly materials and promote the terms such as “decarbonization” and “carbon neutral” in our articles.

* The “biomass ink” used by our company has been certified as a biomass material by the Japan Organic Resources Association and has acquired the biomass mark.

Inquiries TEL: 054-281-9092 (weekdays 9:00 to 17:00)

Email: contact@shizupack.jp

Alternatively, customers can contact us using the inquiry form.

【 Biomass-ink printing Stick Pack Processing Details 】

■ Recommend raw materials for the filling process

Powdered Green Tea

■ Size

Width 25 x Height 110 mm

■ Filling Portion

1g ~ 1.5g (For different portions, please contact us as it depends on the specific weight of different ingredients)

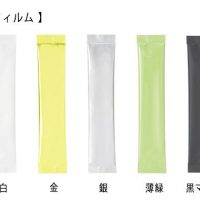

■ The film used for biomass-derived ink printing

In the environmental-friendly biomass ink stick pack, the stamp is printed on the backside of the package. (See image above)

The biomass-derived ink is a mixture of ink components and biomass materials (by using plant-derived materials such as rice bran or seeds).

By switching from conventional ink to biomass ink, the film will become environmental-friendly material that could reduce the amount of CO2 emissions up to about 13% compared to conventional oil-based gravure ink.

■ Features

- Using biomass-derived ink for the printing process to reduce CO2 emissions.

- Easily open just by hand from anywhere on the stick pack without having to use scissors.

- Excellent various barrier characteristics due to containing aluminum.

- Moisture-proof.

- Prevent oxidization.

- Light-shielding.

- Fragrance-retaining.

We also provide service for the stick pack box packing to commercialize the product.

■ Cost

2.2 yen / pack (tax excluded)

Related Products

-

Plain Stick Processing: 50mm Width

Manufacturing 50mm Width Plain Stick Package The stick package’s film has excellent barrier characteristics such as light-shielding, moisture-proof, fragrance-retaining, and some other barrier properties, which are best for food packaging.

-

Stick Manufacturing With Hook Hole For Hanging

We could produce the hook hole stick for hanging, which is rare in stick production with a large capacity.

-

Plain Stick Processing: 40mm Width

Manufacturing 40mm Width Plain Stick Package The stick package’s film has excellent barrier characteristics such as light-shielding, moisture-proof, fragrance-retaining, and some other barrier properties, which are best for food packaging.

-

The Package That Sealed On Three Sides

The square bag with heat-sealed on three sides with a small cutout on the side for open. This tea pack is used for filling powdered teas such as matcha latte, roasted green tea, or several instant drinks.

-

Processing 50mm Width Stick Pack With Hook Hole – Filling Process For ~ 20g Latte Or Instant Coffee (Food Product Included)

We can manufacture 50mm width stick packs with a hook hole on top of the package. The filling process will handle various types of raw ingredients. In addition to granule ingredients filling such as instant coffee, matcha latte, and corn soup, various food ingredients such as rice, wheat, and beans can be filled.

-

Organic Powder Green Tea

Stick pack with 25mm width that is suitable for organic powder green tea raw material. The stick pack's film has excellent barrier characteristics such as light-shielding, moisture-proof, fragrance-retaining, and some other barrier properties, which are best for food packaging. In addition, it is easy to cut and can be opened from anywhere on the pack without using scissors.

![OEM Manufacturing (Drip-Type Pack): Hot Soup [Odashi] With Great Flavor OEM Manufacturing (Drip-Type Pack): Hot Soup [Odashi] With Great Flavor](/wp-content/uploads/2022/03/odashi3_580px-200x200.jpg)

![[50,000 yen per month!!] “Homepage production/Homepage maintenance & management”, “SNS updates” [50,000 yen per month!!] “Homepage production/Homepage maintenance & management”, “SNS updates”](/wp-content/uploads/2019/04/580px_WEB_SITE-200x200.png)

![[Renewal] Whole Catechin Powder Stick Pack Green Color [Renewal] Whole Catechin Powder Stick Pack Green Color](/wp-content/uploads/2022/04/new_marugoto_green-1-200x200.jpg)