TEA BAGS

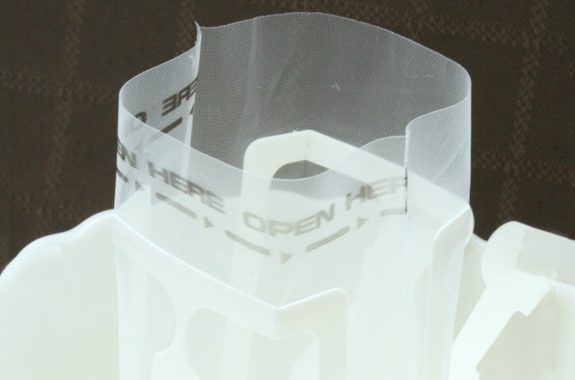

Drip Bag Manufacturing (With “Open Here” Display)

Drip bag tea processing for various tea types such as green tea, black tea, herbal tea, or Chinese tea.

Because of its ease of use and convenience, allow the user enjoy to drink more delicious tea and coffee, it becoming a new trend in recent years.

By displaying the guidance word “OPEN HERE” in English on the tearing line, it’s easy to understand for foreigners to open.

The instruction display is also available in Japanese, so you can choose the one that best suits your need.

Related Products

-

Flat Teabag Manufacturing

Flat teabag has been using in Japan for over 30 years.

-

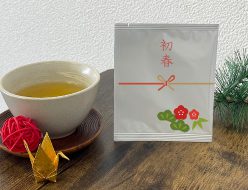

Seasonal Product [New Year]: Individually Wrapped Teabags

For the celebration of the New Year 2022, we producing individually wrapped teabag with a special Japanese Traditional Design for the exterior package.

-

Add more value to products and goods!!

This is a proposal for businesses and retailers wanting of providing further services beyond the sale of products and goods. *If it is related to tea or sweets, we can prepare it for you.

-

Large Capacity Teabag Processing

A large-capacity teabag is ideal for large size tea pitchers.

-

[Seasonal Product For Christmas] “kawaiipack” Product Line

"kawaiipack" is a special product line that has various special designs that aim to make drinking tea looks more fun. And this product will also manufacture with the OEM method. There are many shapes can choose from, such as funny characters, cute animals, favorite wearing clothing, or simple text lines, etc. For Christmas, Santa Clause or Rudolph the reindeer are the most suitable choice.

-

Individually Wrapped Triangular Teabag Processing

In recent years, the demand for individually wrapped triangular tea bags has been rapidly increased. To ensure long-term preservation, each package is individually wrapped and filled with nitrogen.

![[To Businesses Commercialize Cosmetic Products] Cosmetic Powder Filling Process [To Businesses Commercialize Cosmetic Products] Cosmetic Powder Filling Process](/wp-content/uploads/2019/04/3821326_s-200x200.jpg)

![OEM Manufacturing (Drip-Type Pack): Hot Soup [Odashi] With Great Flavor OEM Manufacturing (Drip-Type Pack): Hot Soup [Odashi] With Great Flavor](/wp-content/uploads/2022/03/odashi3_580px-200x200.jpg)

![[50,000 yen per month!!] “Homepage production/Homepage maintenance & management”, “SNS updates” [50,000 yen per month!!] “Homepage production/Homepage maintenance & management”, “SNS updates”](/wp-content/uploads/2019/04/580px_WEB_SITE-200x200.png)